Maximise Your Potential

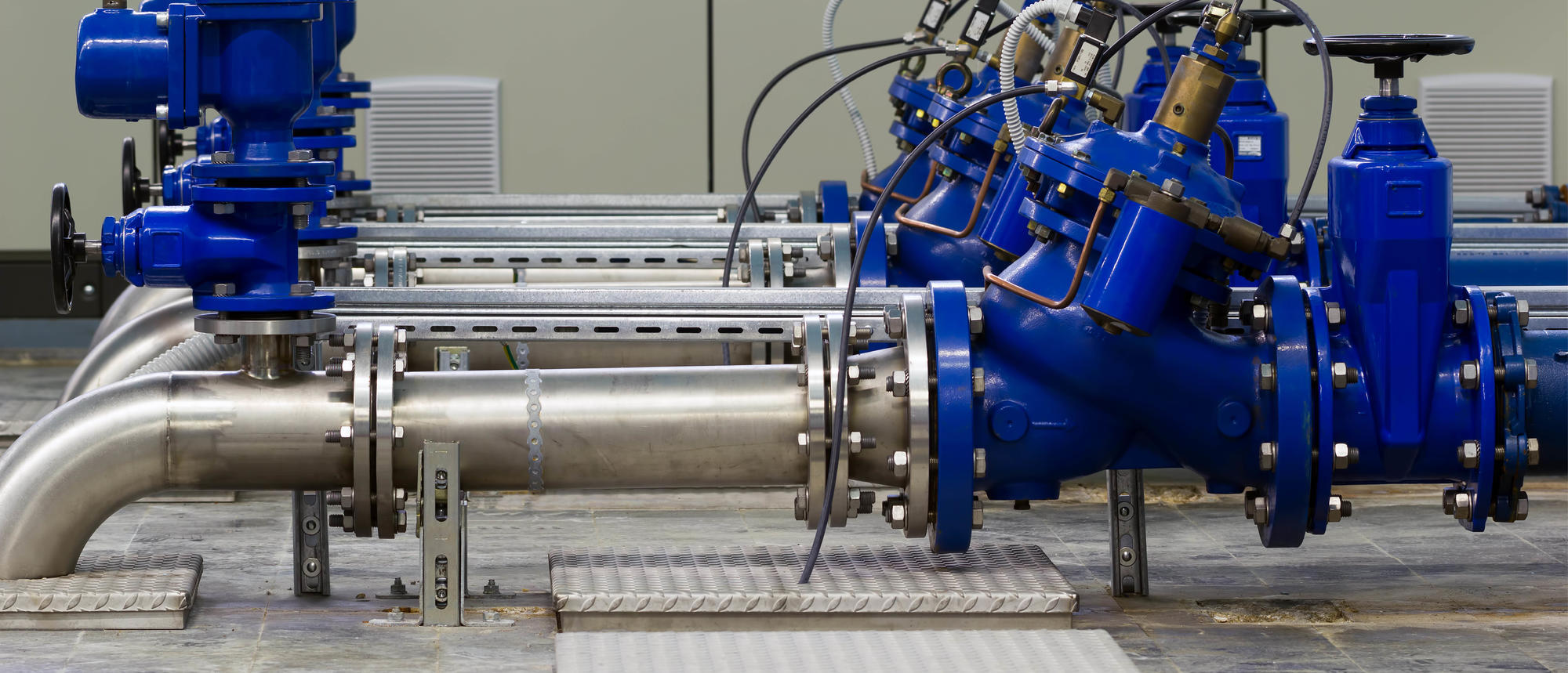

At Nutrien Water, we focus on maximising your potential by drawing on the experience and combined expertise of our national network. Underpinned by a fundamental commitment to customer service, our dedicated team operate across agricultural, commercial, and residential water applications. Combining technical know-how, local experience and expert product knowledge, our team is skilled in determining the most suitable and cost-effective water solution for every customer. Always striving for excellence in water management, Nutrien Water is more than a service provider, we are a valuable partner to your business.